Viessmann Registered Installer in Finchley

Viessmann builds some of the finest boilers in the world. With over a century of German engineering heritage and a commitment to stainless steel construction that few competitors match, these are boilers engineered to last decades — not just meet a warranty period. As a Viessmann Registered Installer, Hilton has the specialist training to service, repair, and install the complete Vitodens range.

Viessmann was founded in 1917 and remains family-owned to this day. Their Inox-Radial stainless steel heat exchangers are manufactured in Allendorf, Germany — one of the most advanced heating technology facilities in the world.

Why Choose a Viessmann Specialist?

Your Viessmann isn't a generic boiler, and it shouldn't be treated as one. Here's why specialist knowledge matters.

Proprietary Diagnostics

Viessmann boilers use a diagnostic protocol that differs from UK-mainstream brands. Pattern recognition across the Vitodens range — knowing which fault codes mask deeper issues — comes only from concentrated experience with these systems.

Stainless Steel Expertise

The Inox-Radial heat exchanger requires different cleaning methods and inspection criteria compared to copper heat exchangers. Incorrect cleaning can damage the passivation layer that protects the stainless steel.

Warranty Protection

As a Viessmann Registered Installer, work carried out by Hilton is recognised by Viessmann for warranty purposes. This matters when you need to make a claim — manufacturer-accredited service records carry significantly more weight.

Direct Parts Access

Registered Installers have direct access to Viessmann's parts network and technical support line — bypassing the delays that non-accredited engineers face when sourcing specialist components.

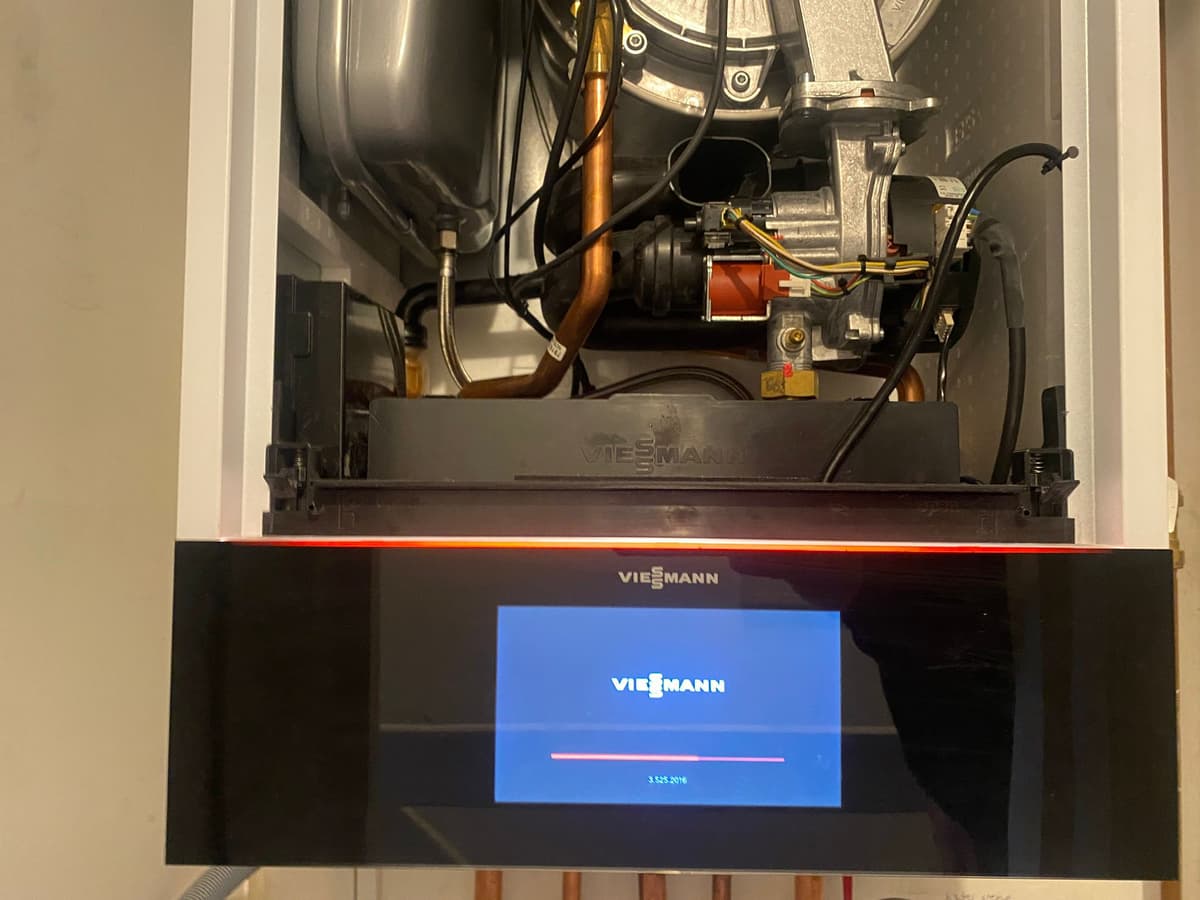

Vitodens Range — Models We Know Inside Out

Every Vitodens model shares Viessmann's core engineering principles, but each is tuned for different property types and hot water demands. Here's what distinguishes them.

Vitodens 050-W

The entry point to Viessmann quality. Don't let "entry-level" mislead you — the 050-W shares the same fundamental engineering as its higher-spec siblings, including the stainless steel Inox-Radial heat exchanger that outlasts copper alternatives by years.

Vitodens 100-W

Viessmann's mid-range workhorse and the model we install most frequently across Finchley. The 100-W adds enhanced controls, a larger integrated display, and marginally higher seasonal efficiency. Compatible with the Vitoconnect module for remote smartphone control.

Vitodens 200-W

Viessmann's flagship domestic boiler. The 200-W features the MatriX cylinder burner for near-silent operation, integrated weather compensation as standard, and the highest modulation ratio in the range — meaning it throttles down to match demand precisely, minimising cycling and maximising efficiency.

Viessmann Fault Code Reference

If your Viessmann is displaying an error code, here's what it means and why it matters. All fault codes require professional diagnosis — these descriptions help you understand the issue before your engineer arrives.

Burner Lockout — Ignition Failure

The boiler has attempted ignition multiple times without detecting a flame. This typically indicates a faulty ignition electrode, gas valve issue, or insufficient gas supply. Requires professional diagnosis — do not attempt to reset repeatedly.

Flame Loss During Operation

The burner successfully ignited but the flame was lost mid-cycle. Common causes include intermittent gas supply, a deteriorating ionisation electrode, or flue blockage causing recirculation. This fault demands immediate attention as it may indicate combustion issues.

Flame Signal at Start-Up (Before Ignition)

The control board detects a flame signal before the ignition sequence has begun — a potentially dangerous condition. Usually caused by a faulty flame detection electrode or PCB issue. The boiler will lock out as a safety precaution.

Repeated Ignition Failure

Distinct from F1, this indicates repeated unsuccessful ignition attempts across multiple cycles. Points to systematic issues — deteriorated electrodes, gas valve malfunction, or air in the gas line. Specialist diagnosis required.

Exhaust Gas Over-Temperature

The flue gas temperature sensor has detected excessive exhaust temperatures, indicating restricted heat transfer through the heat exchanger. Typically caused by internal scaling, blocked waterways, or insufficient system flow. Prompt attention prevents damage.

DHW Charging Fault

The domestic hot water circuit is not charging correctly. On system boilers, this usually relates to the diverter valve or DHW sensor. On regular boilers with a cylinder, check the motorised valve and cylinder thermostat wiring.

Flue Gas Recirculation

The combustion air supply has been contaminated by recirculating flue gases, creating a dangerous condition. The boiler locks out to prevent incomplete combustion. Requires inspection of the flue terminal clearance and surrounding structures.

DHW Outlet Sensor Fault

The hot water outlet temperature sensor is reading outside expected parameters — either open circuit, short circuit, or drifting. Results in erratic hot water temperature control. Sensor replacement by a qualified engineer resolves this.

Different Fault Code?

Viessmann uses an extensive diagnostic system. Email us with your specific fault code and model number for expert guidance.

Report Fault CodeViessmann FAQ

Questions we hear regularly from Viessmann owners across Finchley and North London.

Why are Viessmann boilers more expensive than mainstream brands?

The cost reflects genuine engineering differences — primarily the stainless steel Inox-Radial heat exchanger (versus copper in most competitors), tighter manufacturing tolerances, and more sophisticated control systems. Over a 15–20 year lifespan, the lower repair frequency and superior efficiency typically offset the higher initial cost.

How long should a Viessmann boiler last?

With proper annual servicing, 15–20 years is realistic and common. The stainless steel heat exchanger is the key differentiator here — it resists corrosion far better than copper, which is typically the first component to fail in other brands.

Can any Gas Safe engineer service a Viessmann?

Legally, yes. Practically, we'd advise caution. Viessmann's diagnostic software, calibration procedures, and component specifications differ substantially from UK-mainstream brands. An engineer unfamiliar with these systems may miss fault patterns or misdiagnose issues that a Viessmann-trained specialist would identify immediately.

Do I need annual servicing to keep my warranty valid?

Yes, without exception. Viessmann requires annual servicing by a Gas Safe registered engineer, with completed records in the Benchmark logbook. Missing a service — even by a few weeks — can void your warranty.

What makes the Inox-Radial heat exchanger special?

It's manufactured from a single piece of stainless steel, formed into a cylindrical shape that maximises heat transfer surface area while resisting the acidic condensate that corrodes copper alternatives. This is the single biggest reason Viessmann boilers outlast most competitors.

Are Viessmann parts readily available in the UK?

Most common parts are stocked by UK distributors. However, some specialist components are imported from Germany, which can add 2–5 days to repair times. As a Registered Installer, we maintain direct access to Viessmann's parts network.

Need a Viessmann Specialist in Finchley?

Registered Installer servicing, repairs, and installations across N12 and surrounding areas